PRODUCT CATEGORIES

LATEST NEWS

CONTACT US

Tel:+86 17398395313

Fax :+86 17398395313

Mobile:+86 17398395313

Email: ruiheah@163.com

Whatsapp: +86 17398395313

25kg pp woven bag secondary packaging machine

-

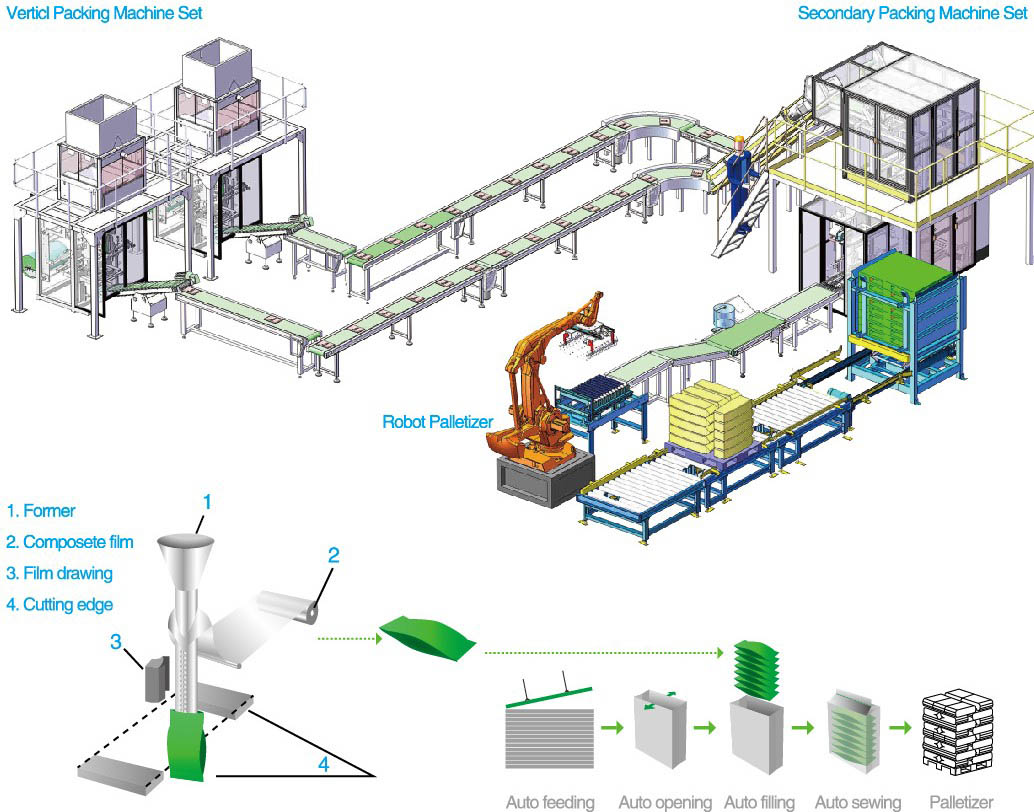

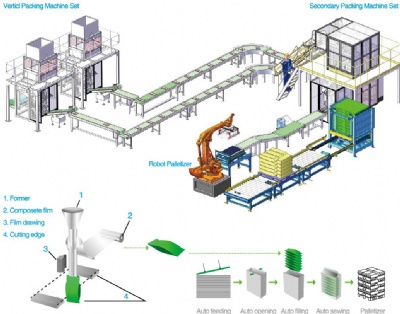

Refers to the equipment that completes the primary packaging of the product and then performs the outer packaging. It is a fully automatic process that automatically loads the products output by the upstream vertical packaging machine into a woven bag and sewing the package according to requirements (arrangement form, quantity, etc.) Packaging process.

Brief Introduction:

Refers to the equipment that completes the primary packaging of the product and then performs the outer packaging. It is a fully automatic process that automatically loads the products output by the upstream vertical packaging machine into a woven bag and sewing the package according to requirements (arrangement form, quantity, etc.) Packaging process.

Product Features:

1. Small bags into big bags, small bags into boxes, labeling equipment, marking equipment, boxing equipment, wrapping and palletizing equipment, etc.

2. The secondary packaging production line for soft bags is mainly to put small bags into big bags (laminated film bags, single film bags or woven bags) or put small bags into cartons and automatically stack them.

3. The equipment composition mainly includes: double-layer inclined conveyor, high-speed conveyor, counting and sorting machine, woven bag automatic packaging machine, sewing machine, product conveyor, etc.

4. This packing unit can realize auto bag feeding,bag opening,counting,filling,moving output,auto sewing, the whole packing process is fully automatic.

5. The touch screen control unit, operation specifications change, maintenance are very convenient, safe and reliable.

6. Can be arranged to achieve a variety of forms to meet different needs of customers.

APPLICATION:

This unit is widely used for packaging of powdery and granular materials like Detergent powder, rice, soy beans, sugar, salt, seeds, corn, peanut butter, chill, pasta, cookies, pet foods, etc. and is the first choice machine of many large companies for secondary packaging.

Work Flow Chart:

Sackets ---Horizontal conveyor---Double slope conveyor --- High speed conveyor ---Bag counting machine ---Automatic bag feeding machine---Auto sewing machine—End woven bag putout.

Technical Parameters:

Packaging range | 150g ~ 5000g sachet products |

Packaging Materials | paper bag, woven bag (lined with PP/PE film) |

Packing speed | 3-10 woven bags / min, (40-120 pouches / min) |

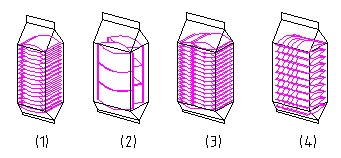

Ranking form | single silo baiting, single row laying, double silo baiting, double row laying |

Air Consumption(Mpa) | 0.5 ~ 0.7MPa |

Gas Consumption(m3/min) | 0.8 |

Power Voltage (v) | 220v/380v 50Hz |

Power (kw) | 5kw |

Packing patterns: