PRODUCT CATEGORIES

LATEST NEWS

CONTACT US

Tel:+86 17398395313

Fax :+86 17398395313

Mobile:+86 17398395313

Email: ruiheah@163.com

Whatsapp: +86 17398395313

1kg sugar salt rice flour bag secondary packaging machine

Brief Introduction:

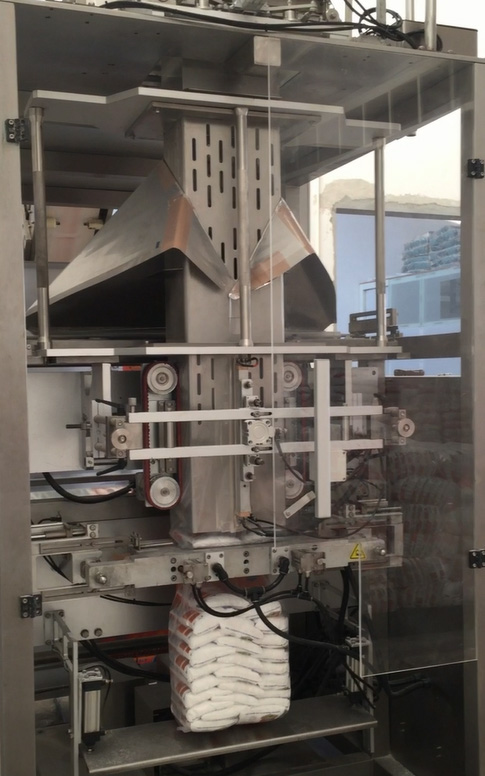

The sugar secondary packaging line also calling sugar secondary packaging line for 1kg pouch, which is widely used for rice, beans, corns, seeds, sugar, salt at small bag from 500g to 5000g packing into big transparent plastic PE film bags, can pack in several packing patterns, its the best way to do balling line, this baling machine is synchronized with one or multi Vertical Form Fill Seal Machine, to complete the packaged pouch products by request order form (one/two/three rows in horizontal) neatly into the baling bag, sealing and take out, capacity can reach maximum 130 small bags into one big bag within one minute.

It achieves from bulk materials to be full automatic secondary packing, saving labors, materials and financial inputs, improving the production efficiency and saving transportation costs with safety storage. The entire packaging line is usually equipped with Robotic Bag Palletizer.

Features:

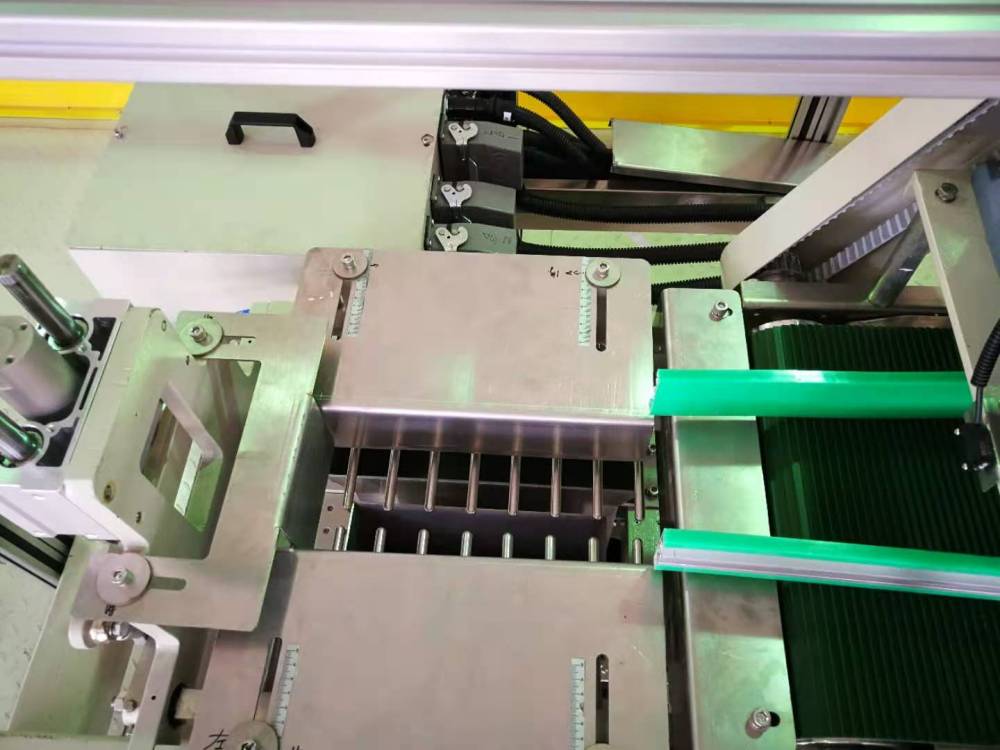

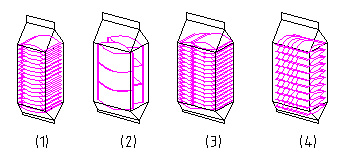

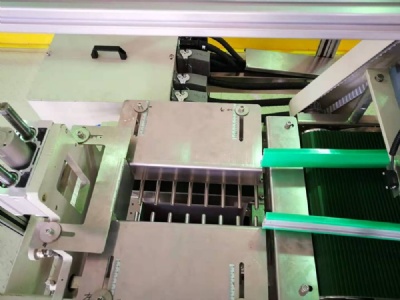

This unit is mainly to complete the fully automatic packaging process of neatly loading the already packaged small bag products (500~5000g) into composite film plastic bags and heat sealing according to the requirements (form of arrangement: single or double-row horizontal grouping etc.). so as to realize fully automatic operation from small pack packaging of bulk material to packaging of composite film plastic bags, save input in manpower, material and financial resources, reduce production cost for customers as well as improve production efficiency. This unit is widely used for packaging of powdery and granular materials like rice, washing powder, salt, sugar, seeds, flour powder, milk powder, etc. and is the first choice machine of many large companies for secondary packaging.

APPLICATION:

Detergent powder, rice, soy beans, sugar, salt, seeds, corn, peanut butter, chill, pasta, cookies, pet foods, etc. This machine can be customized as sugar baling machine and Detergent Powder Packing machine.

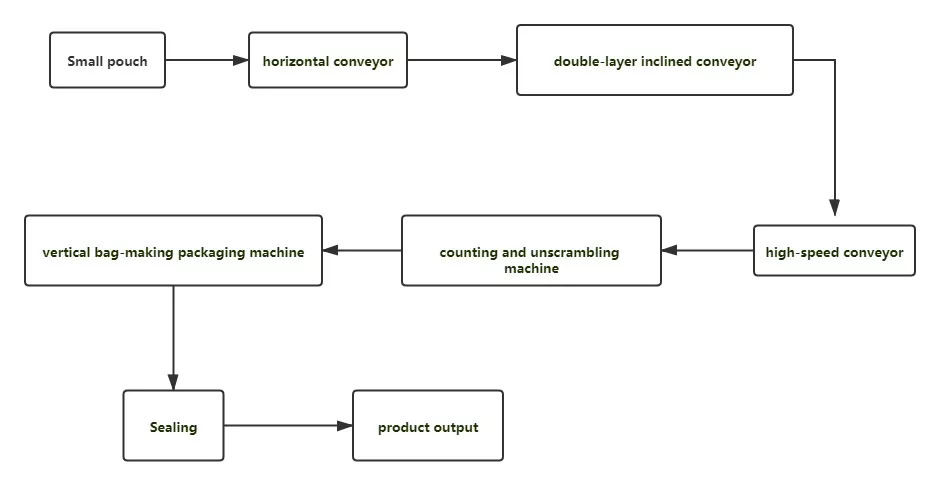

Work Flow Chart:

Small pouch → horizontal conveyor → double-layer inclined conveyor → high-speed conveyor → counting and unscrambling machine → vertical bag-making packaging machine → Sealing → product output.

Packing patterns:

Technical Parameters:

Model(Roll film width) | VFS920 | VFS1100 | VFS1500 |

Bag Length(mm) | 150~600 | 200~900 | 200-1000 |

Bag Width(mm) | 150~450 | 150~530 | 200~730 |

Max Width of Roll(mm) | 920 | 1100 | 1500 |

Type of big bag | Pillow bag, gusset bag (Formed by roll film) | ||

Packaging scope (g) | 500~5000g bagged products | ||

Packaging speed (bags/min) | 4~8 for big bags 60~130 for small pouches | ||

Form of arrangement | Horizontal single or double-row grouping | ||

Air Consumption(Mpa) | 0.65 | 0.65 | 0.65 |

Gas Consumption(m3/min) | 0.5 | 0.5 | 0.5 |

Power Voltage (v) | 220v/380v | 220v/380v | 220v/380v |

Power (kw) | 5kw | 6kw | 6kw |

Weight(kg) | 1000 | 1100 | 1200 |