PRODUCT CATEGORIES

LATEST NEWS

CONTACT US

Tel:+86 17398395313

Fax :+86 17398395313

Mobile:+86 17398395313

Email: ruiheah@163.com

Whatsapp: +86 17398395313

jumbo bag filling machine for 500kg 1000kg polyester

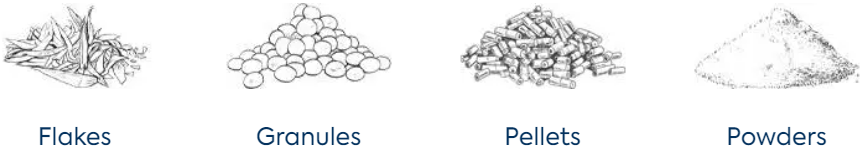

Application:

Such as: PET flakes, PET chips, rPET resins, recycled polyester yarns, PVC flakes, PVC Chips, PVC pellets, PVC granules, polyester granules, polyester flakes, polyester chips, fiber granule etc.

Bag types:

Technical features:

jumbo bag filling machine, big bag filling, bulk bag filler, big bag filling machine, bulk bag filler hopper, big bag filling station, bulk bag filling frame, bulk bag filling equipment.

Gravity feeding mechanism, high-speed loading, greatly increasing output.

Use an automatic bag removal mechanism to reduce labor intensity.

Imported technology touch screen, weighing control instrument, weighing sensor, pneumatic actuator.

Equipped with high-precision AC regulated power supply to ensure stable and reliable operation.

Parts in touch with materials are made of imported stainless steel to make sure a long service life.

Reserved RS232/485 serial port for data communication with the peripheral management system.

Conveyor is optional.

Technical Parameters:

Model | RH-1000K |

Weighing range | 500~1000kg |

Packing speed | 10~30bags/hour |

Interval value | 100g |

Accuracy grade | X(0.2) |

Air consumption | 0.4~0.6MPa 1m3/h |

Power consumption | AC 380V 50Hz 5.8KW |

Install height | 3800mm |

Main configuration:

Name | Brand |

Weighing controller | China |

Load cell | American / Mettler Toledo |

Power switch | Japan / Omron |

Limit switch | Japan / Omron |

Miniature circuit breaker | France / Schneider |

Button,knobs | France / Schneider |

Intermediate relay | France / Schneider |

Cylinder | Taiwan / Airtac |

Solenoid value | Taiwan / Airtac |

Touch Screen / PLC | Genmany / Siemens |

Features:

1. Dust controlled bagging

2. Easy and user-friendly adjustment of different bag sizes

3. Minimum installation effort required

4. Maintenance-friendly construction

5. Ergonomic design for enhanced working environment

6. Economic and environmentally friendly system due to the possibility of re-using bags

7. Ability to handle different types of bag

8. PLC control system with user-friendly operator interface

9. Precise net weighing technology using the SpeedAC controller

10. Low-maintenance components and assemblies

11. Clean working conditions due to limited dust escape in the filling area

Options:

1. Empty pallet magazine with in feed roller conveyor

2. Protection fence for empty pallet magazine

3. Operator platform

4. Out feed roller conveyor with anti-collision protection and induction loop

Our Services:

1. one year guarantee for whole machine except for wear parts;

2. 24 hours technical support by email;

3. calling service;

4. user manual available;

5. reminding for the service life of the wearing parts;

6. installation guide for clients from both China and abroad;

7. maintenance and replacement service;

8. whole process training and guidance from our technicians. High quality of after-sales service symbolizes our brand and ability.

We pursue not only good quality products, but also best after sales service. Your satisfaction is our final purpose.

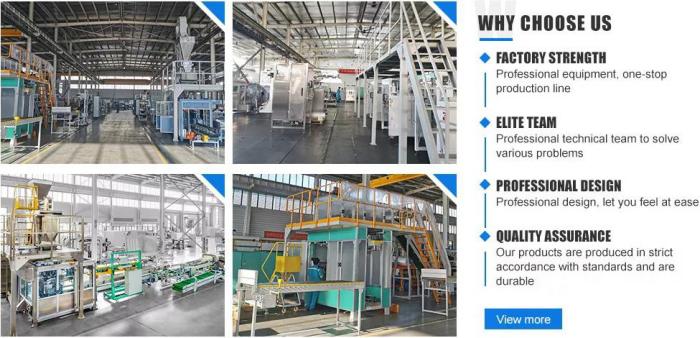

Why Choose Us:

Cooperation:

Packaging & Transportation:

FAQ:

Q1. What is the advantage about your company?

A1. Our company has professional team and professional production line.

Q2. Why should I choose your products?

A2. Our products are high quality and low price.

Q3. Any other good service your company can provide?

A3. Yes, we can provide good after-sale and fast delivery.

Q4.What kind of Transportation could you provide?And are you able to update the production process Information in time after placing our order?

A4. Sea shipping, air Shipping, and international express. And after confirming your order ,we would keep you updated of production details of emails and photos.